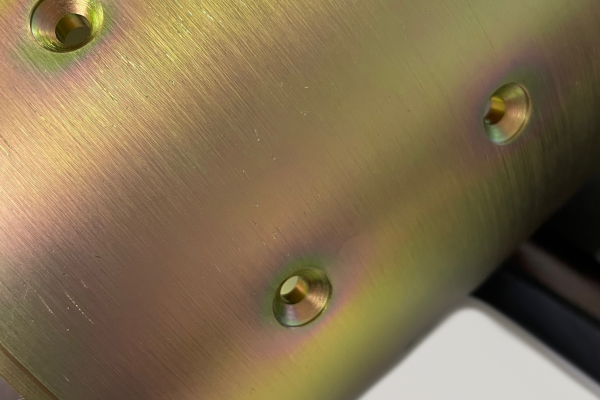

ELECTROLESS NICKEL

Generally used for corrosion resistance. Because there is no current involved, E/N is known for depositing a uniform coating on the substrate. Due to the coating low porosity characteristics E/N creates a solid barrier around the part.

BRIGHT NICKEL

This electrodeposited finish offers great corrosion protection however; bright nickel is usually called upon for aesthetic purposes. The addition of brighteners in the bath provides a bright shine. Because of this characteristic bright nickel is most often used as an undercoat to a polish chrome finish.

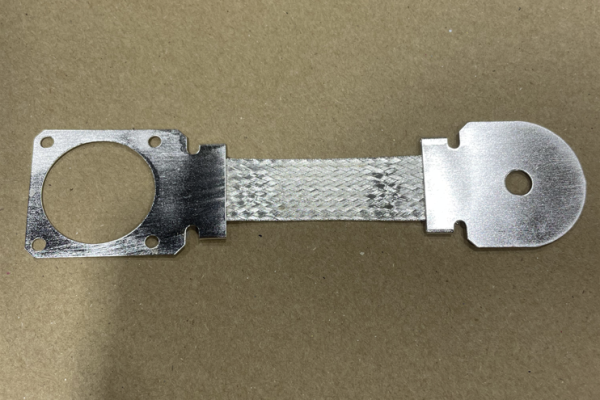

SULFAMATE (DULL) NICKEL

Engineers use dull nickel because of its high pure nickel content. Dull nickel offers corrosion resistance and ductility which is suitable for components that will be flexed or bent.